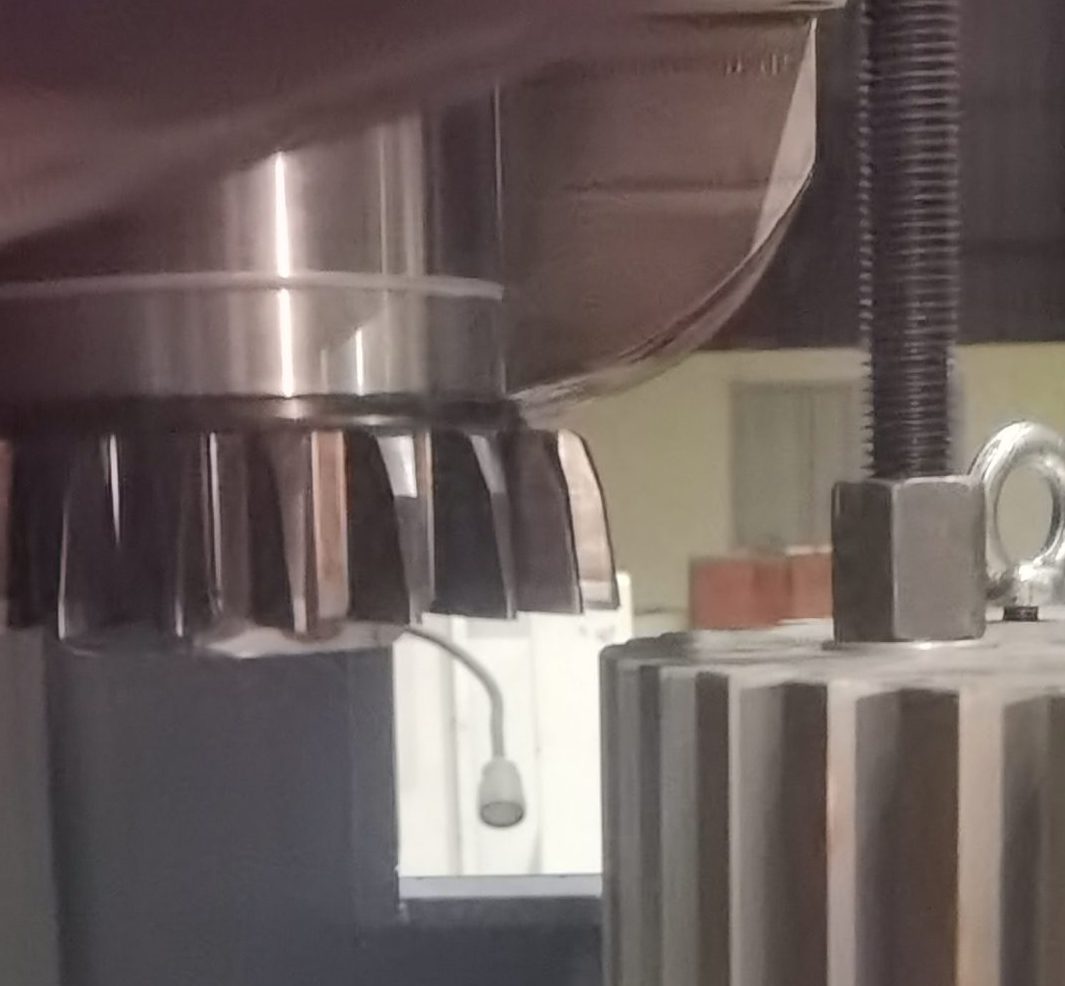

GST Series Pull Type Gear Shaping Machine

Generally, the tool holder part of the gear insertion machine is fixed on the column and cannot be moved up and down along the column (that is, the tool holder does not have the function of lifting and pulling). For the deep hole inner teeth, because it is not convenient for the installation and disassembly of the tool, only a single piece can be manually adjusted and processed. Automatic circular cutting cannot be carried out, and it is difficult to form mass production. For more special deep hole inner teeth Wheel parts, the traditional gear insertion machine seems powerless. The tool holder lifting function of this machine tool solves the problem of deep-hole internal tooth processing that cannot be solved by the traditional gear insertion machine. For many double or multi-link gears, it can also realize one-time clamping and multi-station processing, especially for double gears with strict phase requirements between each gear, it provides a reliable processing guarantee. In addition, the tool holder lifting function also provides a more flexible design space for the design of equipment fixtures.

The main difference of the GST series gear insertion machine is that the tool frame of the gear insertion machine is changed to a movable tool frame body. The main advantages are as follows: 1) Because the stroke position and the stroke length do not affect each other, the maximum stroke length can be used within the adjustment range of the entire stroke position. For the processing of deep-hole inner teeth, there is no waste of empty stroke, which improves the processing efficiency; 2) For multi-linked tooth processing, it can be achieved by one clamping, which improves product quality and processing efficiency; 3) The insertion position can be adjusted at will, which reduces the cost of repeatedly making tooling clamps; 4) The movable tooth insertion tool holder expands the scope and ability of gear insertion, so that the oversized tooth width processing exceeding the maximum processing size of the machine tool can be completed well.

Traction parameters

| Item | GST200 | GST400 | GST600 | GST800 | GST1200 | GST1600 | GST2500 |

| Traction stroke(mm) | 300 | 300 | 300 | 400 | 500 | 500 | 500 |

The rest of the parameters are the same as those of ordinary gear inserts.

Typical workpieces