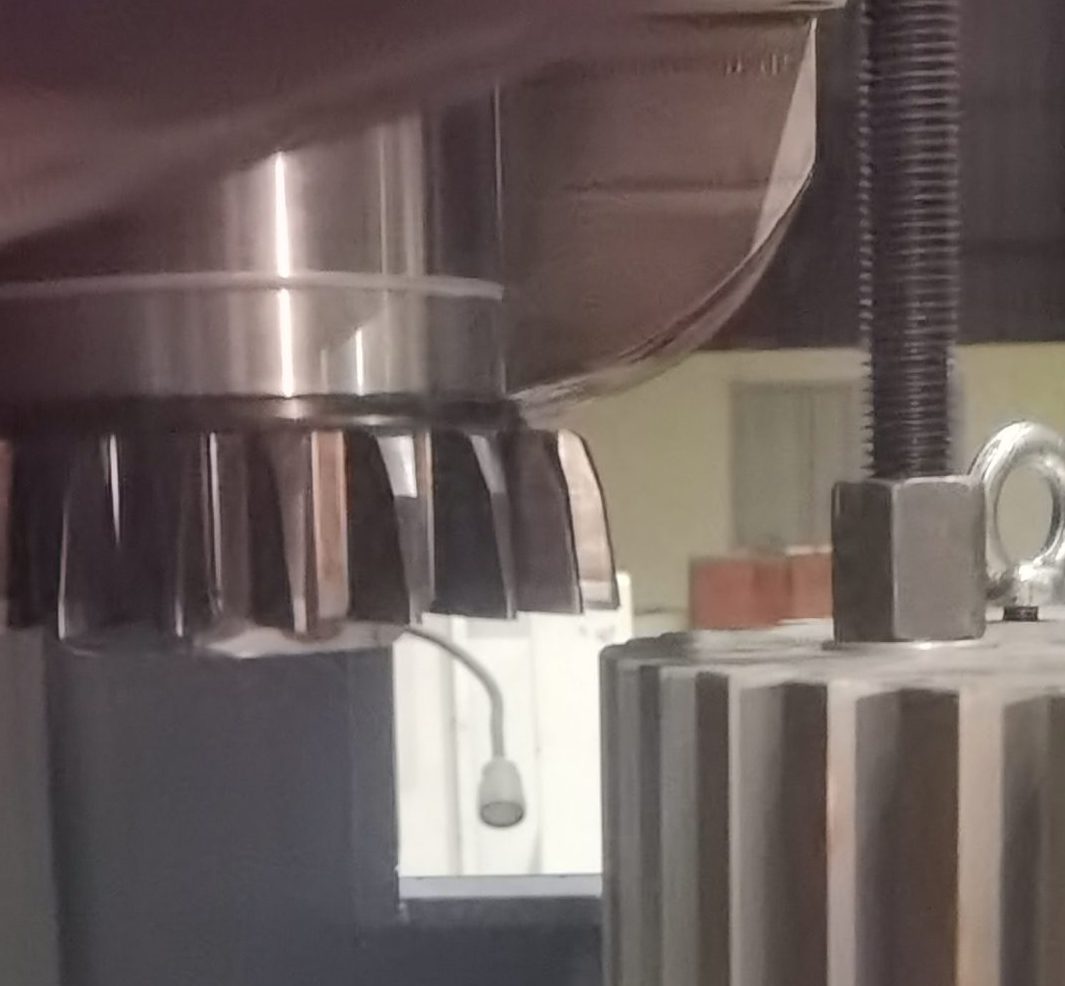

GSE Series Electronic Spiral Guide Gear Shaping Machine

Helical teeth are more and more widely used due to a series of high transmission accuracy, high strength, low vibration and noise. When the inner helical teeth and the outer helical teeth of the small empty knife need to be processed, one method is to process the special guide rails and tools designed according to the workpiece drawings, and the other is to use torque motors to replace the worm...

产品介绍

Helical teeth are more and more widely used due to a series of transmission accuracy, high strength, low vibration and noise. When the inner helical teeth and small empty knife outer helical teeth need to be machined, one method is to process the special guide rails and tools designed according to the workpiece drawings. The other is to use the torque motor to replace the worm gear vice, which is carried out through the electronic spiral guide rail method, which is flexible and suitable for product trial production. For the processing of a variety of oblique teeth, the GSE series electronic spiral rail gear insertion machine has been developed. Based on the modular development of the GS series gear insertion machine, the worm gear vice and main drive motor of the tool holder are changed to direct drive, and the automatic processing of arbitrary slique teeth can be realized with special insertion process software.

As an electronic helical rack machine tool integrating the function of gear cutting, it is equipped with more abundant features, including the following:

●Electronic spiral guide rail function, processing straight teeth and any oblique teeth.

● Portable tool holder, lifting function;

● Long stroke automatic adjustment function;

● Configure servo knife function.

● Configure the most advanced CNC system of Siemens, seven-axis five-axis linkage.