GS200 High-efficiency and High-precision Gear Shaping Machine

The GS200 high-efficiency and high-precision gear shaping machine is a high-efficiency gear shaping machine developed based on the latest gear shaping process and combined with Liebherr's latest technology. It is mainly used for the efficient processing of gears in new energy vehicles, motorcycles, agricultural machinery, construction machinery and other industries. The processing accuracy is stable and meets the national standard level 6.

Advantages

The most advanced gear shaping technology in the world is adopted, and the gapless transmission technology is fully applied to ensure the high rigidity and high efficiency of the product. The wear-free technology ensures the precision stability of the product, and the processing precision is stable at the national standard level 6.

1. The X-axis adopts steel guide rails and rolling element gapless transmission technology, which is more suitable for spiral cutting. The linear axis movement torque is more stable and the CPK can reach 1.67.

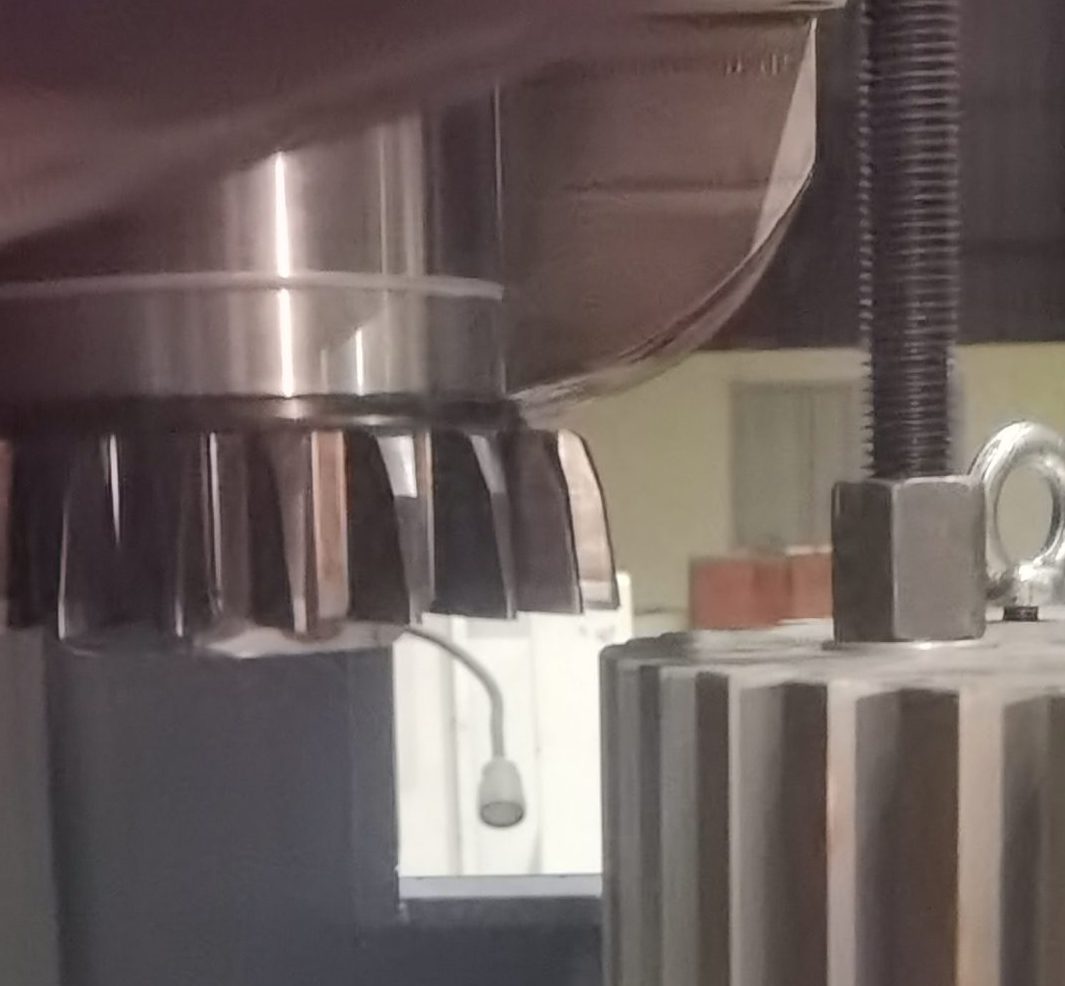

2. Hydrostatic tool holder: maximum linear speed 90m/min, average linear speed 60m/min.

3. Static pressure small insert technology: no gap, no wear, ensuring long-term stability of tooth accuracy.

4. Torque motor direct-drive workbench: equipped with Heidenhain grating ruler to achieve gapless transmission of the workbench and stable gear shaping accuracy of level 6.

5. Configuration of main purchased parts: Hydraulic station: Japan Nachi; Screw: Japan NSK, Taiwan PMI; System: Siemens 828D; Bearings: FAG, NSK, IKO.

Specifications

| No | Item | Parameters |

| 1 | Maximum working diameter external gear/internal gear (mm) | 300 / 130+D knife |

| 2 | Maximum modulus (mm) | 4 |

| 3 | Maximum tooth width (mm) | 90 |

| 4 | Max. travel length of gear shaper (mm) | 100 |

| 5 | The main shaft stroke number of the hobbing cutter (str/min) | 60-1500 |

| 6 | Machine tool shaft diameter (mm) | 85 |

| 7 | Workbench diameter (mm) | 320 |

| 8 | Workbench Aperture (mm) | 100 |

| 9 | Adjustment of the stroke position of the tooth cutter (mm) | 30 |

| 10 | Diameter of the installation shaft neck of the tooth cutter (mm) | 31.743 |

| 11 | The distance from the hob shaft centerline to the table centerline (mm) | -70~275 |

| 12 | Spindle face to worktable distance (mm) | 140-270 |

| 13 | Main motor power (Kw) | 5.5 |

| 14 | Total Power of Machine Tool (Kw) | 14 |

Products