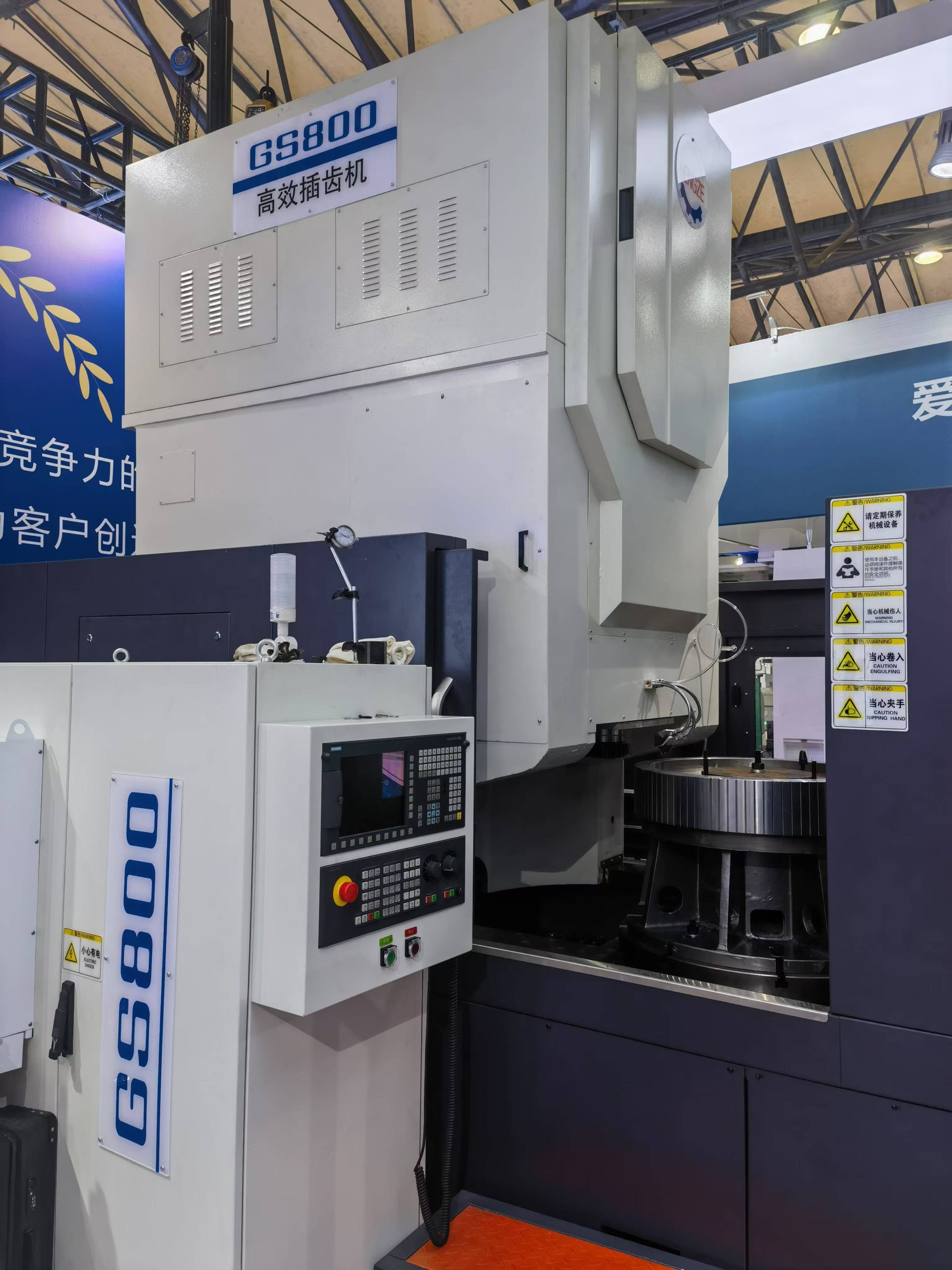

GS800 Efficient gear shaping machine

GS800 high-efficiency gear insertion machine is a high-efficiency gear insertion machine developed based on the latest product characteristics of domestic engineering machinery, wind power, mines, general reducers and other industries. The processing efficiency is about twice that of similar products.

Advantages

1. The workbench is standardly equipped with double worm gear worm mechanism, static pressure structure, high rigidity and no wear;

2. The bed body adopts a steel rail structure,

3. The tool spindle adopts the latest static pressure technology, which can be dynamically monitored and adjusted;

Specifications

| No | Item | Parameters |

| 1 | Maximum working diameter external gear/internal gear (mm) | 800 / 1100 |

| 2 | Maximum modulus (mm) | 12 |

| 3 | Maximum tooth width (mm) | 280 |

| 4 | Max. travel length of gear shaper (mm) | 300 |

| 5 | The main shaft stroke number of the hobbing cutter (str/min) | 30-400 (无级) |

| 6 | 刀具主轴直径(mm) | 140 |

| 7 | Workbench diameter (mm) | 900 |

| 8 | Workbench Aperture (mm) | 320 |

| 9 | Adjustment of the stroke position of the tooth cutter (mm) | 50 |

| 10 | Diameter of the installation shaft neck of the tooth cutter (mm) | 44.443 |

| 11 | The distance from the hob shaft centerline to the table centerline (mm) | 0-730 |

| 12 | Spindle face to worktable distance (mm) | 270-620 |

| 13 | Total Power of Machine Tool (Kw) | 43KW |

Products

12 modules, 42 teeth, hardness HB300, tooth width 132mm, 5.5 hours of processing, far ahead of peers.