Efficient gear milling machine

High-efficiency gear milling machine is a cost-effective cutting machine developed by domestic and foreign customers for large gear processing. It can be used for roughing and finishing of finished products before hobbing. It is mainly used in wind power, engineering machinery, mining machinery and other fields.

The gear milling machine adopts a forming tool cutting gear with the same groove shape as the gear to be machined, that is, the cutting edge shape of the tool used coincides with the groove shape of the gear to be cut. It is mainly used for roughing, heat treatment first half finishing and final processing in some industries.

The core components of the high-efficiency gear milling machine are the milling head and the workbench, which are the top priority to ensure the accuracy, efficiency and stability of the gear milling machine. The GM series high-speed gear milling machine is realized through modularization on the basis of the gear hobbing machine, that is, the hobbing frame is replaced with a high-rigidity milling head. The workbench is the same as the GH series gear hobbing machine, and the machine tool has high processing efficiency, good stability and high accuracy.

Specifications

| Project/Model | GM1600 | GM2000 | GM3000 | GM4000 | GM5000 | GM6000 |

| Maximum modulus(mm) | 26/32 | 26/32 | 32/40 | 32/40 | 40 | 40 |

| Disk diameter (mm) | φ360~400 | φ360~420 | φ380~420 | φ400~480 | φ400~480 | φ400~480 |

| Shaft diameter (mm) | 90 | 90 | 90 | 100 | 100 | 120 |

| Maximum helix angle ° | ±25 | ±25 | ±25 | ±25 | ±25 | ±25 |

| Maximum outer diameter of the gear ring in (mm) | 1800 | 2200 | 3200 | 4500 | 5500 | 6500 |

| Processed minimum outer ring outer diameter (mm) | 145 | 450 | 450 | 1500 | 2100 | 3000 |

| Minimum inner diameter of the gear ring (mm) | 600 | 600 | 600 | 600 | 700 | 700 |

| The distance between the center of the blade and the back wall (mm) | 620 | 620 | 620 | 650 | 650 | 650 |

| The distance between the center of the knife plate and the countertop (mm) | 600-1350 | 600-1350 | 600-1650 | 600-1650 | 600-1850 | 600-2000 |

| Workbench Repeatability Positioning Accuracy " | ≤±3 | ≤±3 | ≤±3 | ≤±3 | ≤±3 | ≤±5 |

| X/Z axis repeat positioning accuracy (mm) | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

| Spindle speed (rpm) | 40-170 | 40-170 | 40-170 | 40-170 | 40-170 | 40-170 |

| Spindle runout (mm) | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

| Workbench top diameter (mm) | 1500 | 2000 | 2500 | 3200 | 3500 | 4000 |

| Worm gear diameter (mm) | 1400 | 1850 | 1850 | 2800 | 2800 | 3600 |

| Workbench maximum load (kg) | 12000 | 20000 | 25000 | 30000 | 40000 | 50000 |

| Total power of machine tools (Kw) | 80 | 80 | 80 | 100 | 110 | 120 |

| Machine tool weight(tons) | About 40 | 约45 | 约65 | 约75 | 约85 | 约100 |

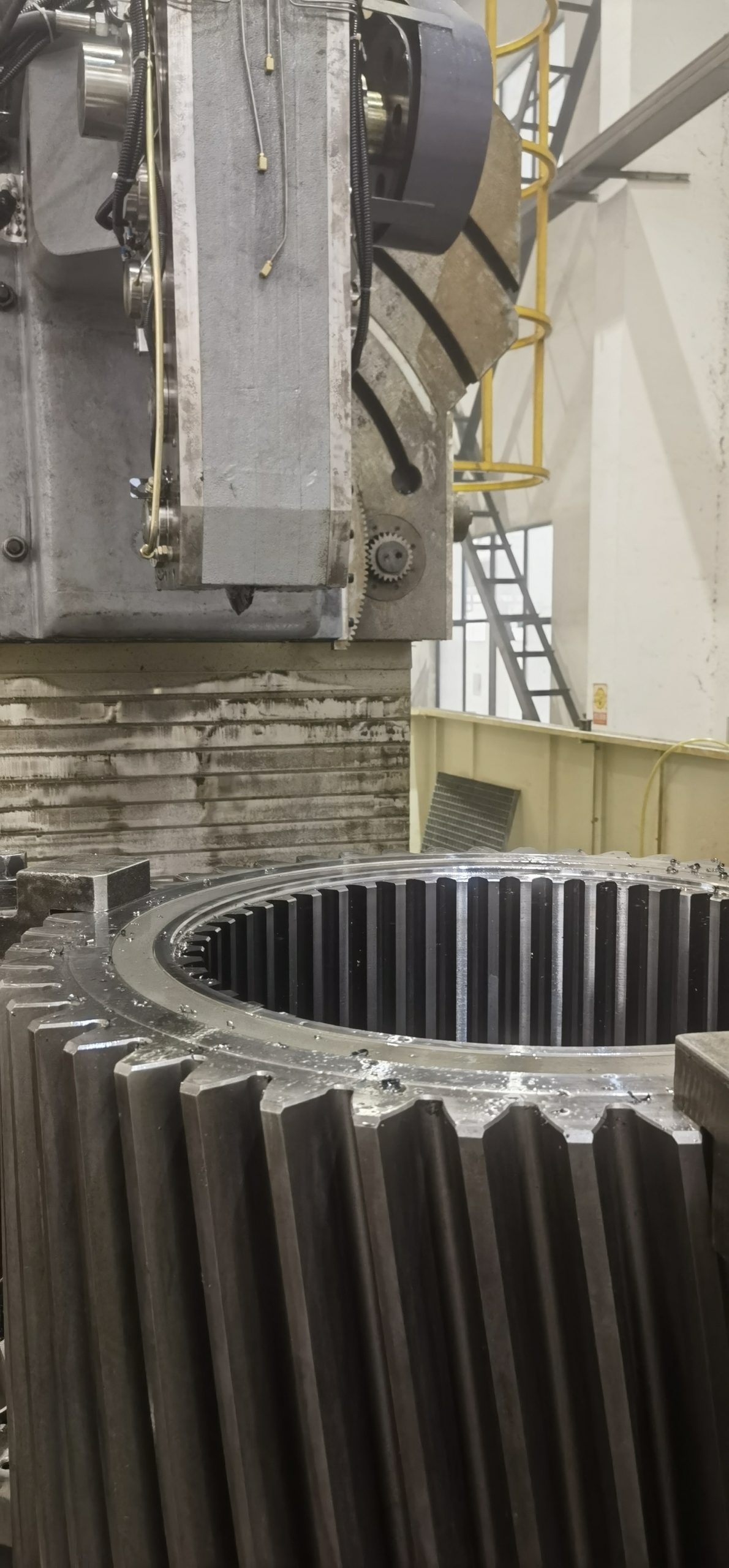

Product image

The minimum inner tooth processing diameter is 400mm

Typical workpieces

Processing video

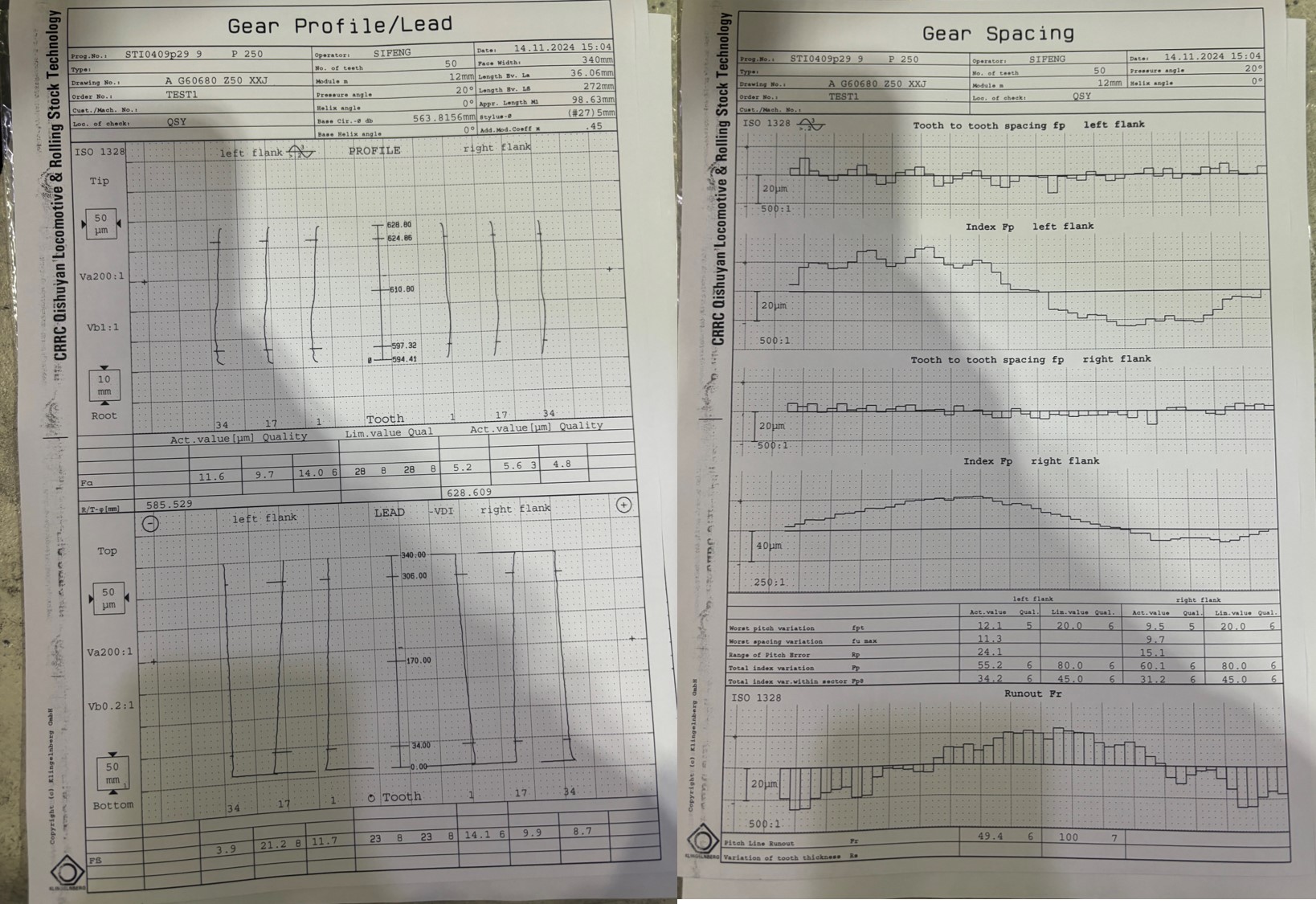

12模数小齿圈精铣

Milling tooth accuracy

Devices

Our Devices